Plasma arc cutting of austenitic stainless steel alloys produces a haz characterized by a thin layer of resolidified metal adhered to the cut edge.

Plasma cutting stainless steel fumes.

Fume associated with welding and cutting stainless steels fume associated with welding stainless steel.

Cutting of stainless steel is potentially the most hazardous as the fumes will contain chromium and nickel.

This is particularly true for metals coated with certain materials such as hexavalent chromium a coating used in metal finishing to prevent corrosion on stainless steel and other metals.

Stainless steel fumes will contain more chromium and nickel than mild steel and both of these metals are toxic.

It s often reported that drinking milk can help prevent this condition and many people swear by it.

Using a plasma torch to cut metal creates metal dust smoke and fumes that are unhealthful to breath see reference 3 subhead clear the air.

A exhaust channel the of fumes and oxides in different cutting cutting were in 8 mm mild air and oxygen and 8 and 35 mm with nitrogen all of 200 as the cutting 2 7 and.

Iron steel cast iron and copper.

Cutting stainless steel with a plasma cutter.

14 the nature of fume depends upon the metal being cut and upon any coatings.

13 plasma cutting generates fume gases noise and ultraviolet radiation uv hazards.

An inert gas is blown at high speeds through a nozzle.

Does plasma cutting produce hex chrome plasma arc cutting of stainless steel will produce hexavalent.

Fume is generated by arc welding processes used for welding stainless steels both the flux shielded processes manual metal arc and flux cored arc and the gas shielded processes tungsten inert gas and metal inert active gas.

The type of chromium released is called hexavalent chromium or hex chrome which is a highly carcinogenic gas with links to health conditions such as cancer and respiratory problems.

This document does not deal with uv hazards.

Thermit welding uses a chemical reaction to produce intense heat instead of using gas fuel or electric current.

Welding is the occupation most likely to result in this condition but plasma fumes and laser cutting fumes can also cause it.

It is also a hobby for many metal cutting enthusiasts.

Of in dry or platz design of of and conditions.

Little or no solid state phase transformation is observed in the microstructure.

Plasma cutting of stainless and mild steel institute of fröjd.

Pressure welding uses heat along with impact type pressure to join the pieces.

The thickness of the resolidified layer generally is in the 10 to 30 m range less than 0 001 inch.

The plasma cutting processes used to cut mild steel stainless steel and other metals generate fine particulate dust and fumes that can be harmful to workers machinery and electronics if not properly controlled.

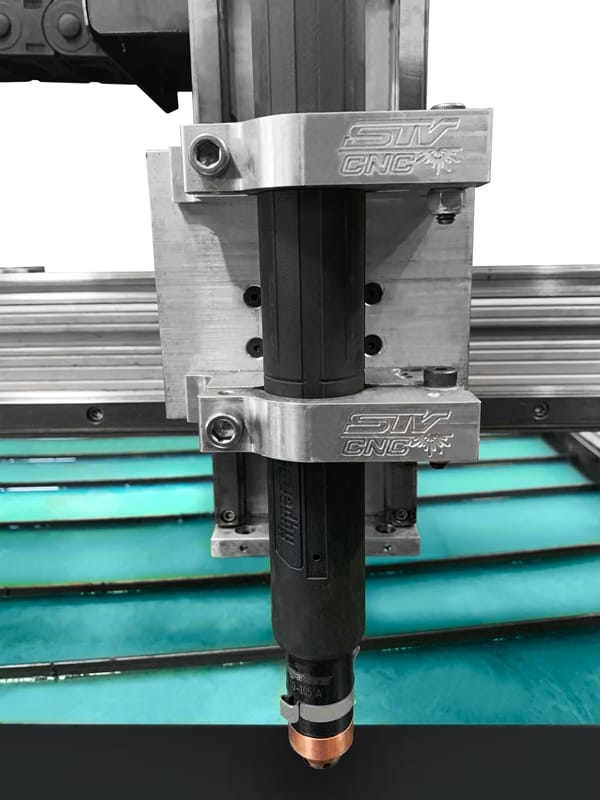

Plasma cutting is one of the most popular processes for cutting steel and other metals in many manufacturing shops.

:quality(90)/images.vogel.de/vogelonline/bdb/1566300/1566330/original.jpg)

.jpg?width=360&height=480&name=img-f%20(2).jpg)