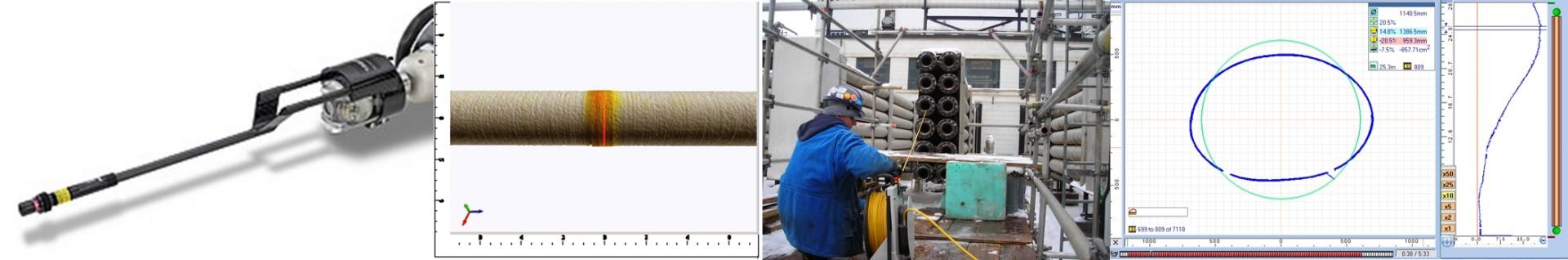

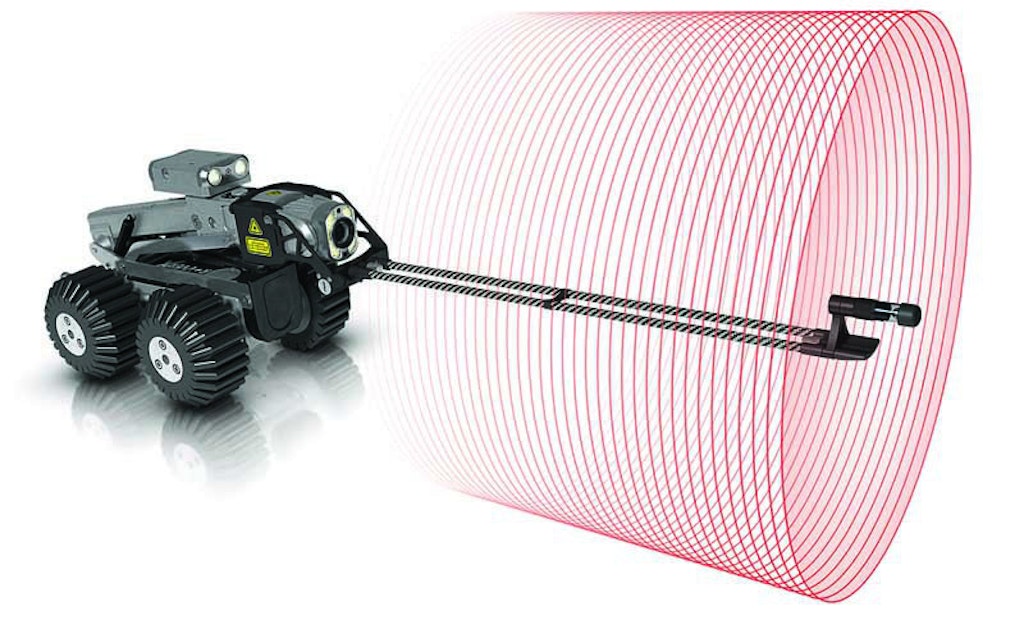

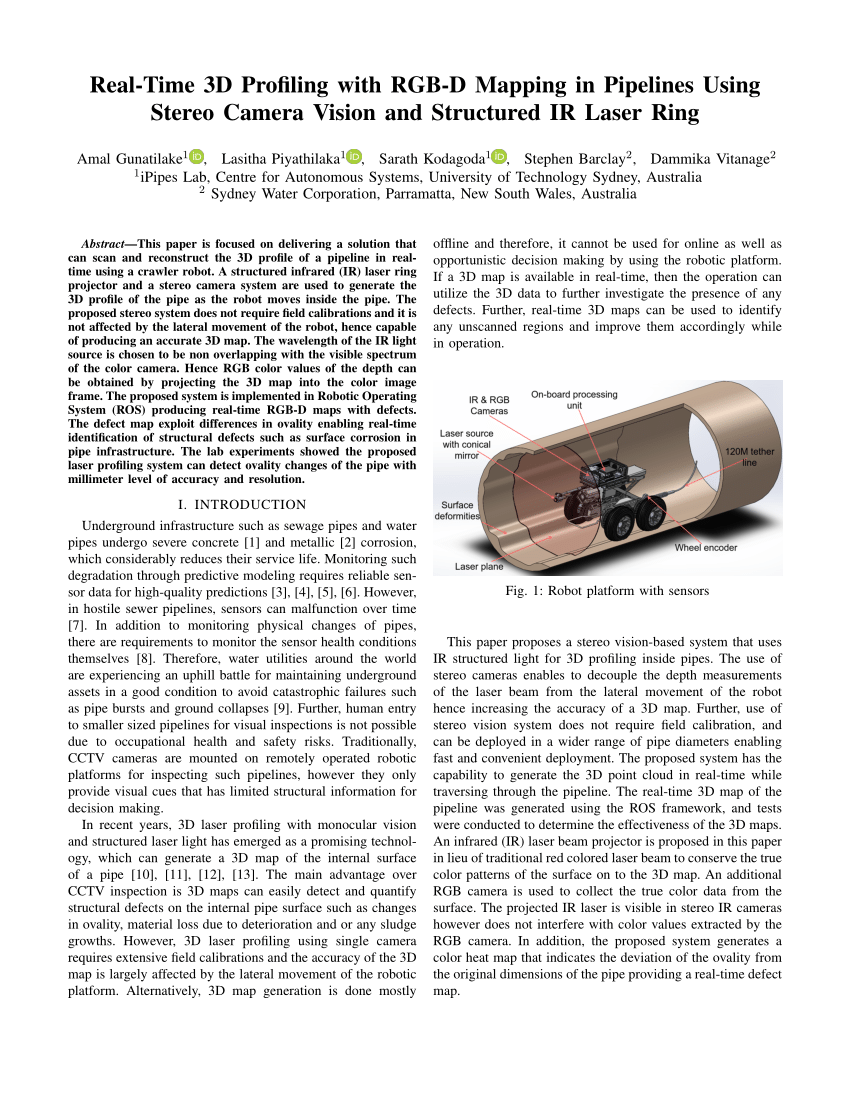

This pipeline laser tool projects a ring of laser light onto the internal surface of the pipe and as the camera moves through the pipe it keeps the laser image in its field of view.

Pipeline laser profiling.

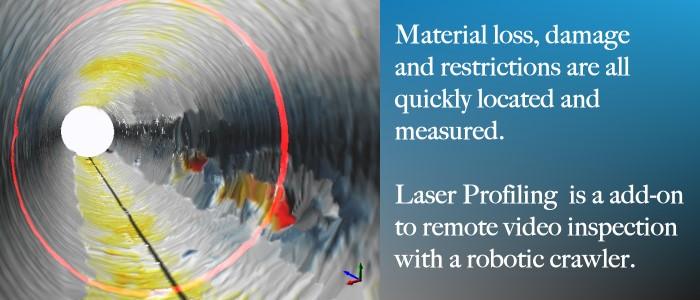

Laser profiling is used with cctv cameras and also as a survey tool to record and measure the extent of damage within a pipe.

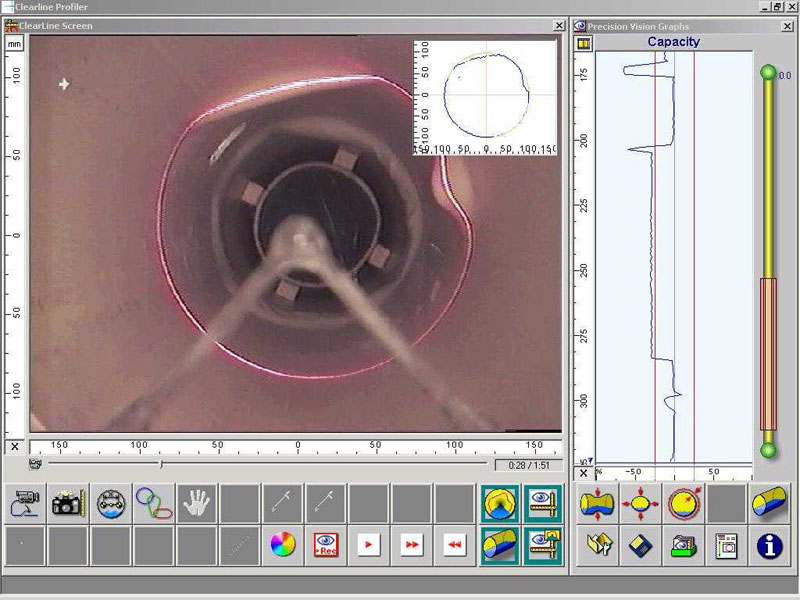

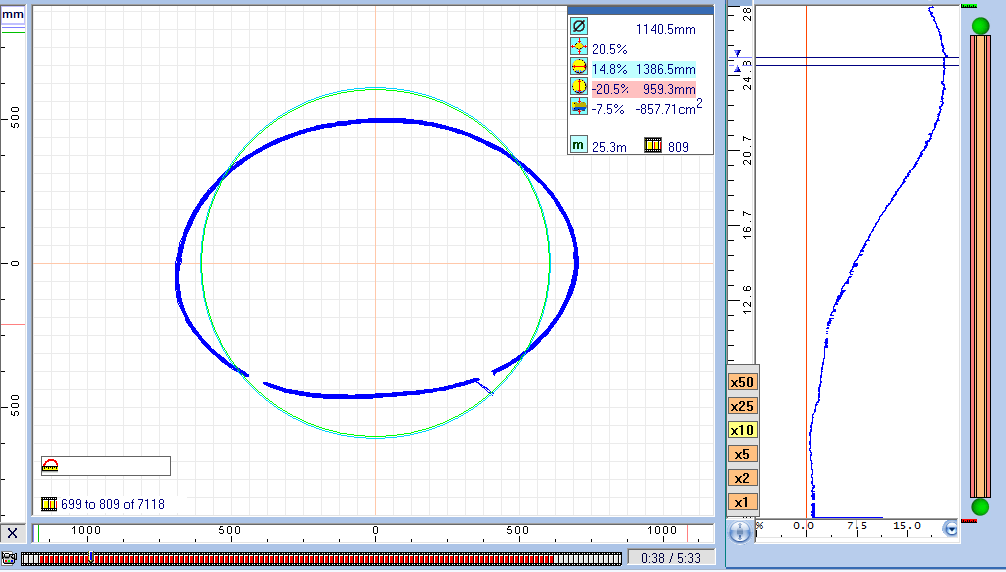

Analysis is performed on the ring of light using the laser profiler software to build a digital pipe profile.

The system can be deployed from portable or vehicle mounted systems.

Laser profiling equipment is attached to existing cctv cameras.

Our technology pipe vision staff were involved in the pioneering of laser profiling systems in new zealand many years ago.

Abergeldie s laser profiling system provides computer generated pipe profile data.

Pipe vision has employed some of the most experienced cctv operators with proven track records in order to become the best inspection company in the industry.

A ring of laser light is projected onto the internal pipe surface.

Using laser profiling in conjunction with cctv our technicians collect survey data and create pipeline reports regarding the measurement of faults and other features inside the pipeline.

Lidar pipe profiling accurately assesses pipeline condition.

Our staff have captured on cctv hundreds of kilometres of mainline trunk sewers throughout new zealand including boat works and laser profiling.

We own and operate the cues digital universal camera duc ready technology that we plug into various cues inspection modules to provide laser profiling for sewers.

Laser profiler software creates a digital profile of the pipe which can be used on a tv inspection vehicle or remote computer.

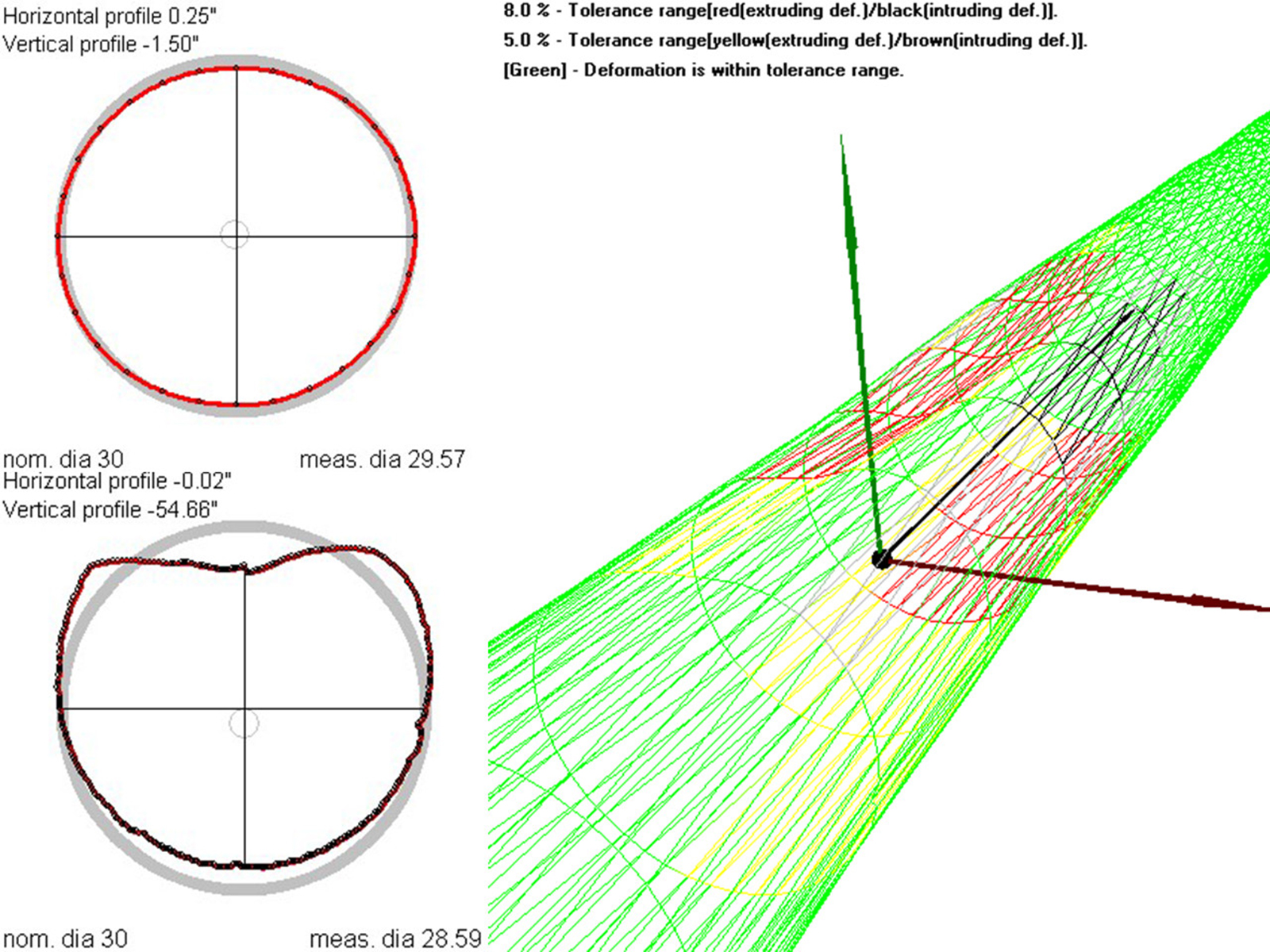

With laser profiling we can get extremely accurate pipeline measurements to analyse the ovality alignment diameter and capacity of a pipe using projected laser light.

This data includes measurements of pipe size laterals water levels and other features as well as automatic analysis of pipe ovality and capacity up to 30.

The laser profiler assesses the condition of a pipe by measuring the internal diameter ovality roundness and capacity of a length of pipeline.

The two methods of laser profiling are direct measurement and laser light ring.

A sophisticated suite of software tools are available to work with the data you capture to give you exactly what you need.

This includes measurements of pipe size laterals water levels and other features as well as automatic analysis of pipe ovality.

Laser profiler system the laser profiler is designed to provide the contractor municipality or consulting engineer with the ability to determine internal pipeline conditions prior to and or after rehabilitation.

The system projects a laser ring on the pipe wall which is recorded for data analysis.

For use with live or pre recorded to video tape cd or dvd.

In situ footage is captured.